For aluminium alloy aviation plate products, new alloys and new sizes can be customized by Flat-Rolled Product Division of Nanshan Aluminium according to customers’ requirements. With the two (27m / 54m) roller hearth furnaces and the 80MN stretching machine, stable plate properties and low internal stress can be achieved; along with 27m aging furnaces, the production of plates in various sizes can be fulfilled. On requests of the customers, cuts convenient for taking arrival re-inspection coupons can be reserved on the plate products. In addition, Flat-Rolled Product Division of Nanshan Aluminium is endeavoring to develop various alloy products and making a good effort in meeting customers' requirements.

Product Type and Specification

7050-T7451 6.35~177.8mm×800~3800mm×1000~14000mm

2024-T351 6.35~101.6mm×800~3800mm×1000~14000mm

7075-T651 6.35~200 mm×800~3800mm×1000~14000mm

7075-T7351 6.35~88.9mm×800~3800mm×1000~14000mm

Product Properties

Alloy Temper:7050-T7451

|

Thickness |

Sampling Orientation |

Tensile Strength/MPa |

Yield Strength/MPa |

Elongation/% |

|

6.3~51.0 |

L |

510 |

440 |

10 |

|

LT |

510 |

440 |

9 |

|

|

>51.0~76.0 |

L |

505 |

435 |

9 |

|

LT |

505 |

435 |

8 |

|

|

>76.0~102.0 |

L |

495 |

425 |

9 |

|

LT |

495 |

425 |

6 |

|

|

>102.0~127.0 |

L |

490 |

420 |

9 |

|

LT |

490 |

420 |

5 |

|

|

>127.0~152.0 |

L |

485 |

415 |

8 |

|

LT |

485 |

415 |

4 |

|

|

>152.0~178.0 |

L |

475 |

405 |

7 |

|

LT |

475 |

405 |

4 |

Alloy Temper:2024-T351

|

Thickness |

Sampling Orientation |

Tensile Strength/MPa |

Yield Strength/MPa |

Elongation/% |

|

6.3~12.5 |

LT |

440 |

290 |

12 |

|

>12.5~25.0 |

LT |

435 |

290 |

7 |

|

>25.0~40.0 |

LT |

425 |

290 |

6 |

|

>40.0~50.0 |

LT |

425 |

290 |

5 |

|

>50.0~80.0 |

LT |

415 |

290 |

4 |

|

>80.0~100.0 |

LT |

395 |

285 |

4 |

Alloy Temper:7075-T651

|

Thickness |

Sampling Orientation |

Tensile Strength/MPa |

Yield Strength/MPa |

Elongation/% |

|

6.3~12.5 |

LT |

540 |

460 |

9 |

|

>12.5~25.0 |

LT |

540 |

470 |

7 |

|

>25.0~50.0 |

LT |

530 |

460 |

5 |

|

>50.0~60.0 |

LT |

525 |

440 |

4 |

|

>60.0~80.0 |

LT |

495 |

420 |

4 |

|

>80.0~90.0 |

LT |

490 |

400 |

4 |

|

>90.0~100.0 |

LT |

460 |

370 |

2 |

Alloy Temper: 7075-T7351

|

Thickness |

Sampling Orientation |

Tensile Strength/MPa |

Yield Strength/MPa |

Elongation/% |

|

6.3~12.5 |

LT |

475 |

390 |

7 |

|

>12.5~25.0 |

LT |

475 |

390 |

6 |

|

>25.0~50.0 |

LT |

475 |

390 |

5 |

|

>50.0~60.0 |

LT |

455 |

360 |

5 |

|

>60.0~80.0 |

LT |

440 |

340 |

5 |

Product Features

7050:with high strength, high toughness and high stress corrosion resistance properties.

7075: with high strength for 7075-T651 temper, relatively high fracture toughness for7075-T7351; with excellent stress corrosion resistance and exfoliation corrosion properties.

2024: with high tensile strength and yield strength under natural aging condition, along with good machinability properties.

Product Application

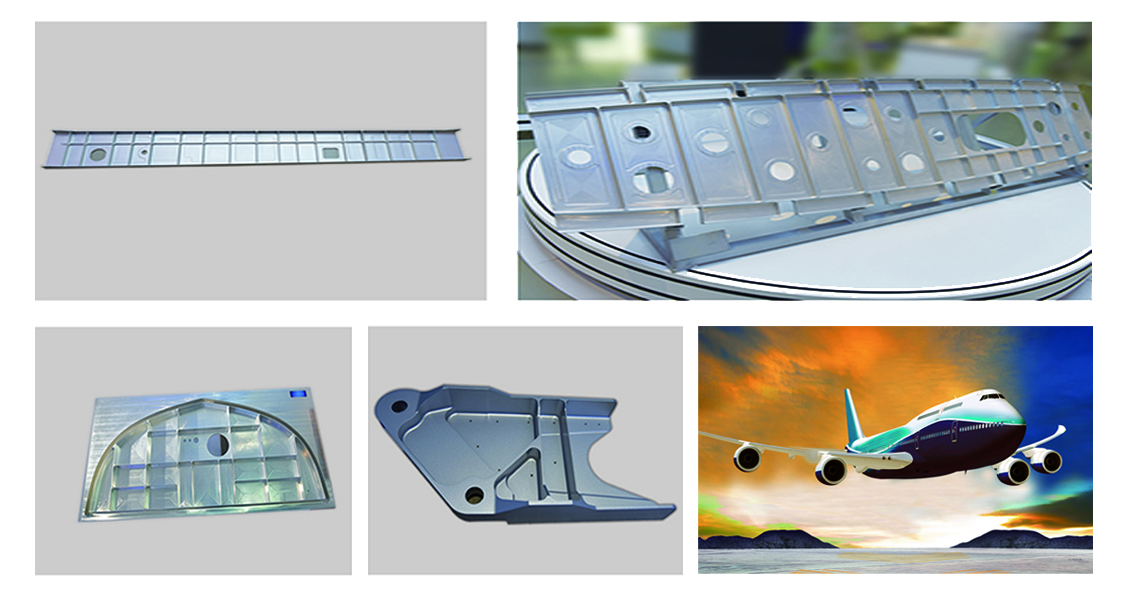

7050: mainly used for aircraft wing ribs, fuselage frames, structural beams, load-bearing structural parts and auxiliary panels.

7075: used for the main structural parts with thick and large sections and bearing high loads, such as beams, wing top skins, and fuselage bulkheads.

2024: mainly used for fuselage skins, bulkheads, wing bottom panels, wing ribs and other positions.